Quality Control

Home » Quality Control

RAW MATERIAL INSPECTION

Inspecting the incoming material quality is the primary step of QC. The purpose is to eliminate quality problems from the essential period.

ROUTING INSPECTION

Our QC engineer inspects semi-finished products routinely every day to prevent quality defects which might be occurred during the production process.

FINISHED PRODUCT BATCH TEST

To guarantee a passed ratio 100%, internal product batch test would be implemented routinely.

We provide various test facilities as mentioned below:

Chemical Analysis

Tensile Strength Test

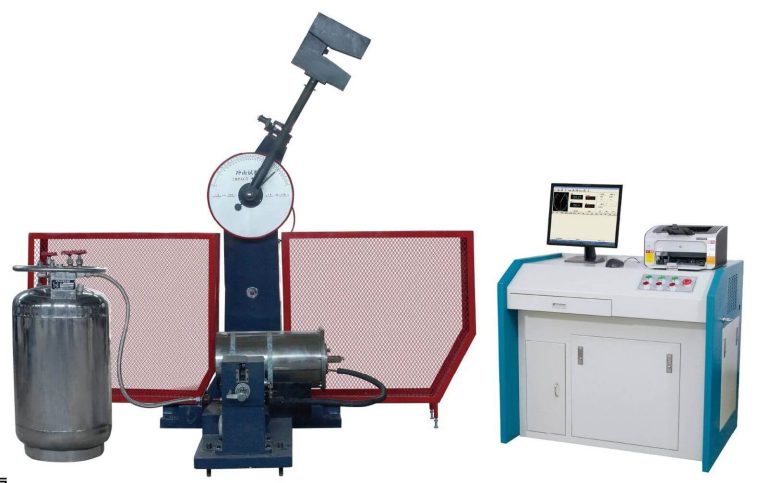

Impact Test

Hardness Test

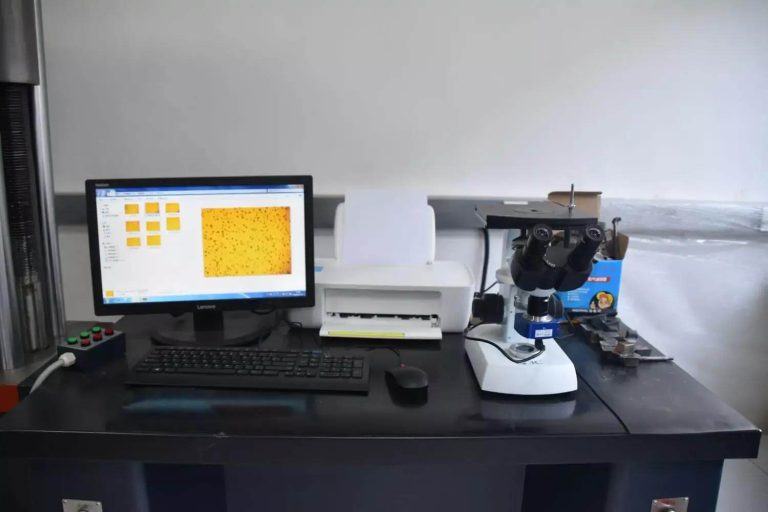

Metallography detection

Magnetic particle test (MT)

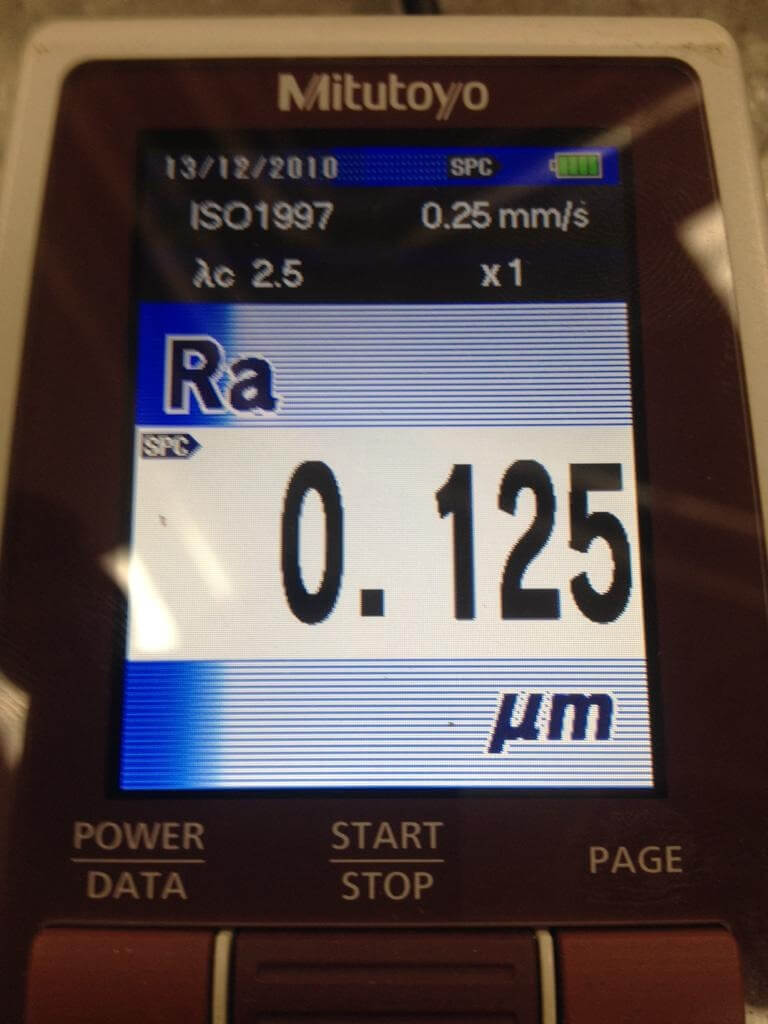

Surface Roughness Test

Three Coordinate Measuring Machine ( CMM ) Test

EX-FACTORY INSPECTION

After batch tests, products will be inspected carefully before delivered out of factory. This process can effectively control the product defects.

QUALITY

You will always be welcome

To get a quotation or discuss about the cooperation